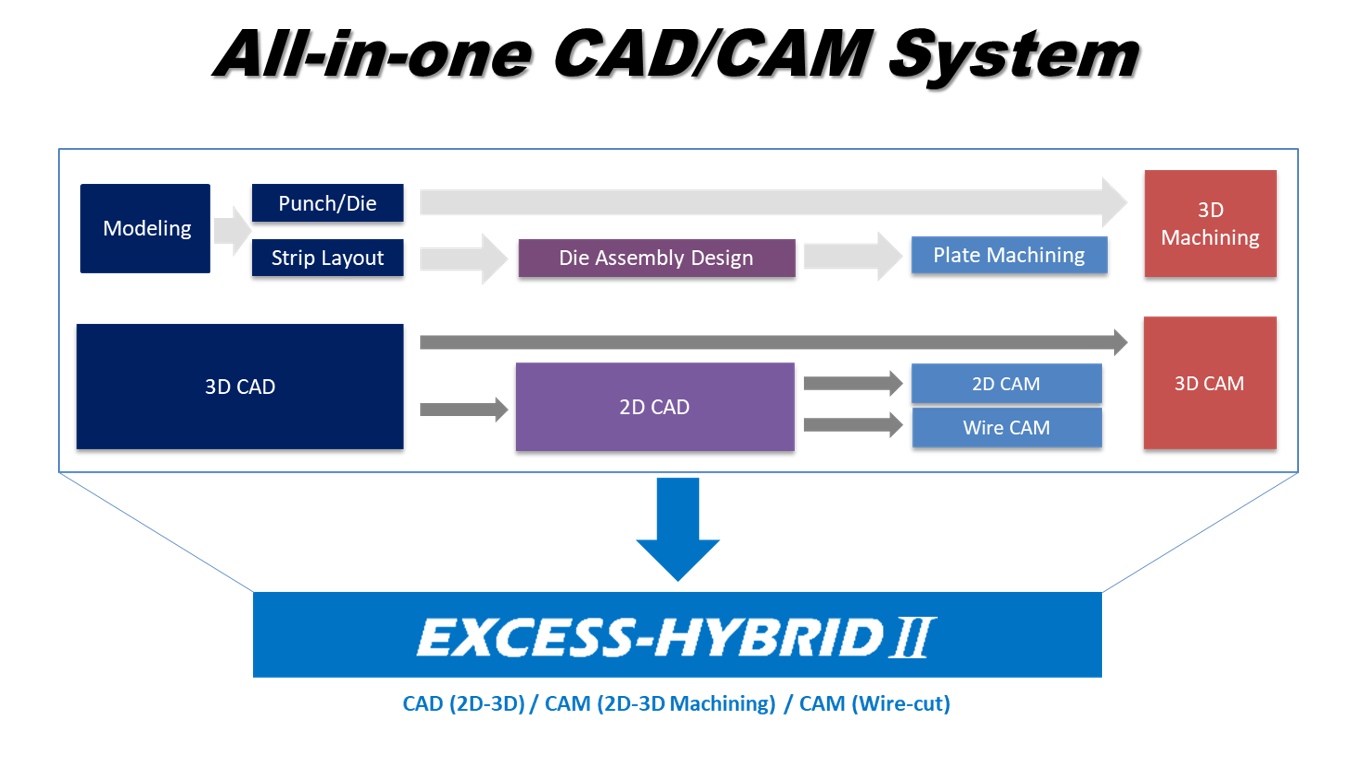

The demand for efficient and operational improvement is increasing year by year. Mold/die design and manufacturing are no exception. The EXCESS-HYBRID II, CAD/CAM Software for Progressive Press Die Manufacturing has been equipped with 3D CAM function since 2020, enabling support for 3D machining in addition to hybrid design support for 2D and 3D. Based on the concept of "ALL IN ONE SYSTEM", the functions of this product have been expanded to meet market demand.

The impetus for the development of this function came from the desire to make it possible to perform all processes from designing to manufacturing of mold/die in a single program, regardless of whether they use 2D or 3D.

Before, the EXCESS-HYBRID II has supported CAM with 2.5D type functions. With the recent increase in demand for 3D type CAM due to the complexity of mold/die shapes, the use of a separate program or outsourcing to an outside vendor that handles 3D CAM has been time-consuming and incurred additional costs. Such tasks increase costs and work hours, and make it difficult to manage operations. Therefore, CGS has developed this 3D CAM function, considering the importance of using 3D CAM on a single program.

From this year's new version (Ver8.1), the following new functions have been added to 3D CAM to improve accuracy and work efficiency.

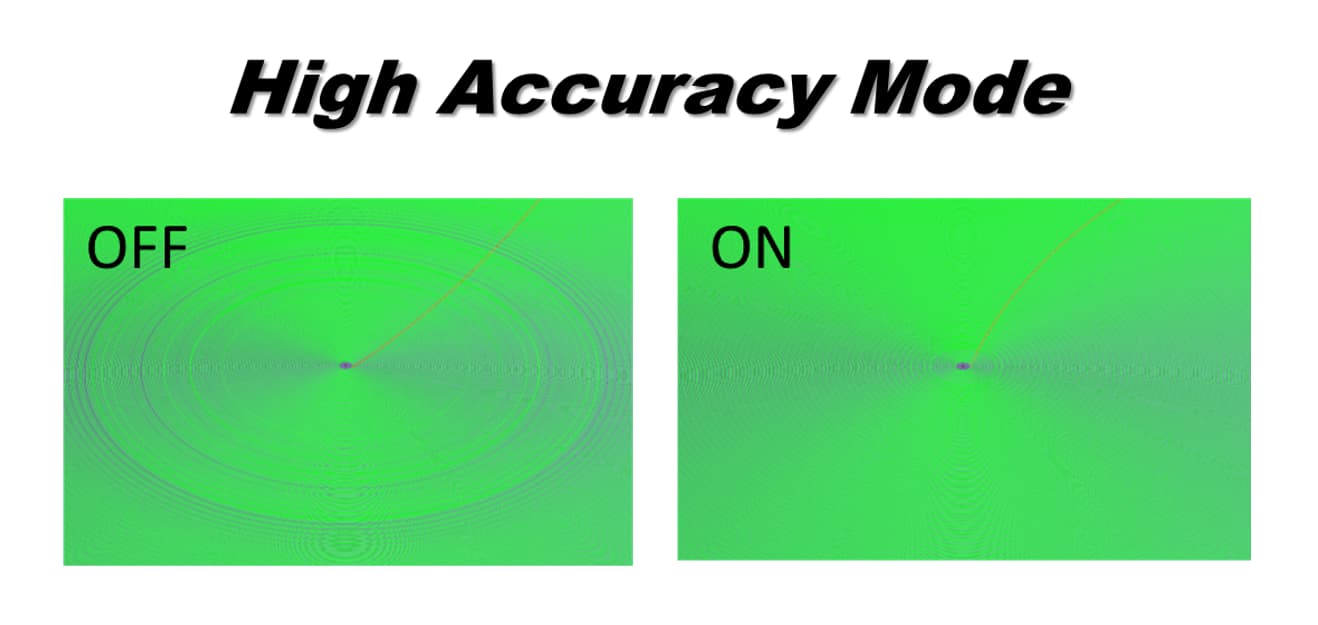

1.High Accuracy mode

A "High Accuracy Mode" has been added that is suitable for machining fine shapes using small-diameter tools. By activating this mode, scale calculation is performed to achieve high-quality workpiece surfaces. The path accuracy can be specified down to 0.1 micron, resulting in a smooth and beautiful workpiece surface after machining and saving time for polishing.

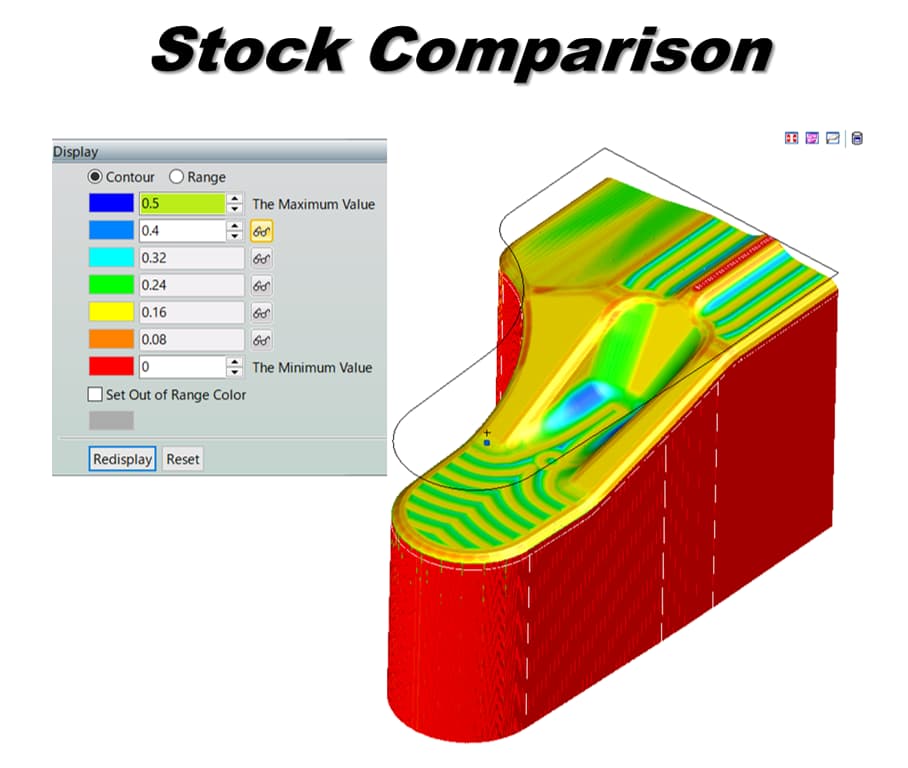

2.Stock Comparison

A "Stock Comparison" function has been added to display the difference from the product model in a specified color. This function allows comparison of the calculated model and the product model. The specified range values are displayed using 7 different colors in contour or range representation, allowing for the confirmation of the uncut amount of material or the presence of overcutting. This helps to shorten the verification process.

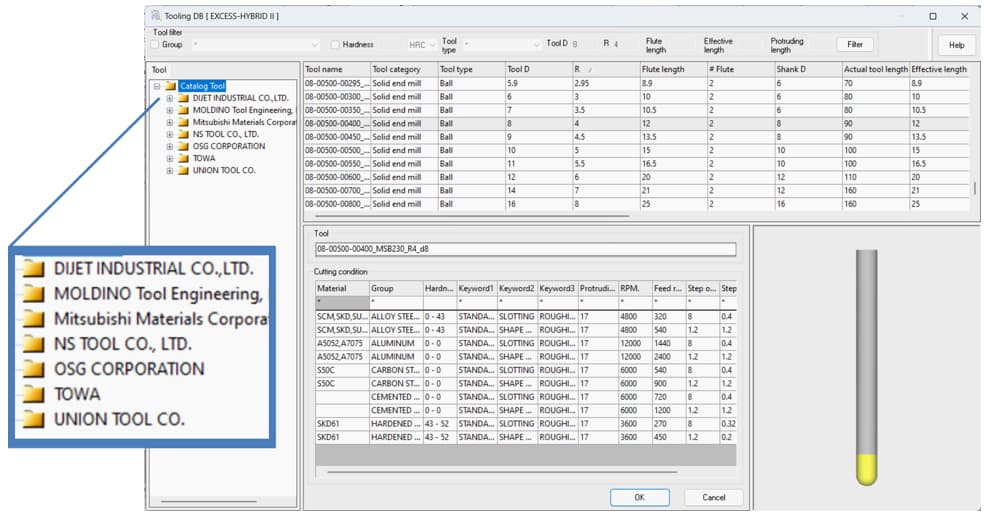

3.Tool Catalog

Equipped with catalog information of major tool manufacturers in Japan. Milling tool sizes and manufacturer-recommended cutting conditions can be referenced, and machining processes can be created from this information.

CGS also offers CAM-TOOL software . Since it is a CAD/CAM software for mold/die manufacturing, it is suitable for milling with high fine surfaces. The development team has utilized some of the features of the excellent CAM-TOOL software to achieve the 3D CAM functionality of EXCESS-HYBRID II.

Benefits of utilizing 3D CAM function

✔ In-house production saves costs for outsourced machining.

✔ Improve operational efficiency through an integrated system.

✔ Expectations for future features. Since CGS is a software developer, it can deliver user requests directly to development. This makes it possible to create a user-friendly system and possiblely meet the request speedily.

Please Wait

Please Wait